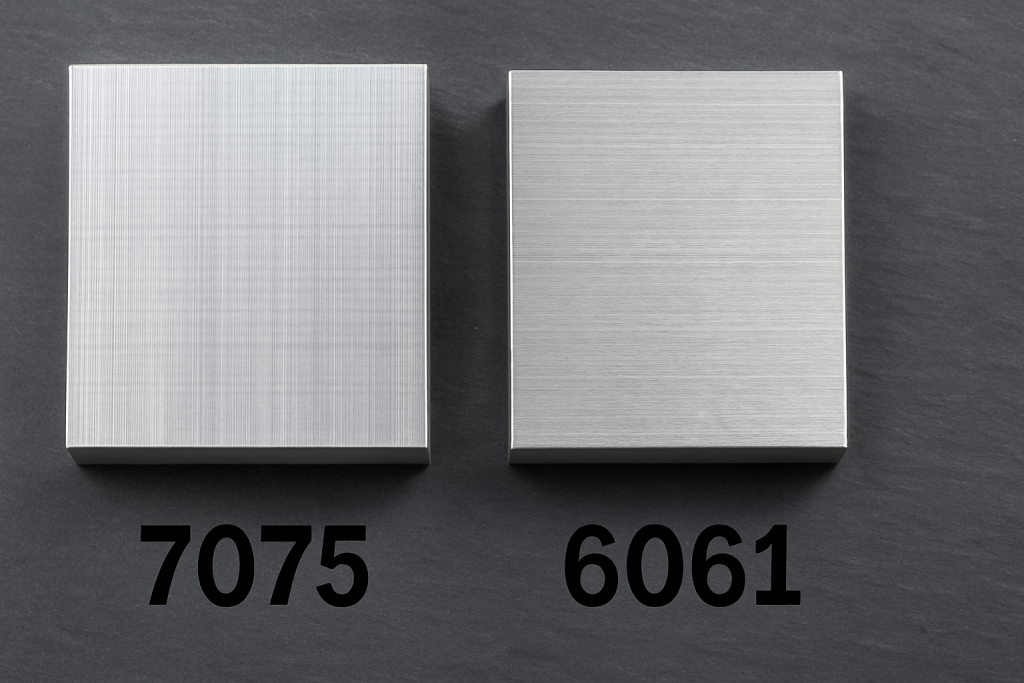

Aluminium 7075 vs 6061 – Aluminium is one of the most widely used materials across industries due to its versatility, lightweight nature, and resistance to corrosion. But not all aluminium is created equal. Among the many available grades, two stand out for their performance and popularity—7075 and 6061. Each has unique properties, advantages, and applications. If you’re unsure which one fits your project best, this guide will help clarify the differences in a way that not only informs but also brings you closer to a reliable supplier that understands your needs: PT Alexindo.

Aluminium 7075 vs 6061: Choosing the Right Alloy with PT Alexindo

The Strength of 7075: Built for Extreme Performance

Aluminium 7075 is known as one of the strongest aluminium alloys available commercially. It was originally developed for aerospace and military applications and has continued to be a go-to material where maximum strength is a top priority. With zinc as its primary alloying element, 7075 boasts superior tensile strength and fatigue resistance, making it ideal for parts that must withstand high stress and pressure.

If you’re building aircraft structures, performance bikes, climbing gear, or anything where failure is not an option, 7075 may be the best choice. It performs well under intense loads and resists wear and tear even in demanding environments. Its ability to hold up against mechanical stress without deforming gives manufacturers the confidence they need for mission-critical applications.

However, this strength does come at a cost. 7075 aluminium is more expensive than 6061, and it is less weldable due to its lower ductility. It also does not perform as well in corrosive environments without additional coatings. That’s why choosing the right supplier is crucial—someone who understands the nature of the material and can guide you through the right preparation and finishing options.

The Versatility of 6061: The Industry Favorite

Where 7075 is known for strength, 6061 is celebrated for versatility. This alloy offers a balanced mix of good strength, excellent corrosion resistance, weldability, and cost-effectiveness. It is one of the most commonly used aluminium alloys worldwide, and for good reason. It’s easier to machine and fabricate, making it a preferred choice for builders, engineers, and designers across countless industries.

From architectural frameworks and marine components to vehicle parts and consumer products, 6061 shines in almost every environment. It responds well to heat treatments, can be anodized for improved appearance and protection, and maintains a consistent, reliable performance across indoor and outdoor applications. It’s also far easier to weld than 7075, making it ideal for structures that need assembly on-site or later modifications.

At PT Alexindo, we supply 6061 in multiple forms including extrusions, tubes, and sheets. Our engineering support team works closely with clients to help determine how best to use 6061 in their specific project. Whether you’re building industrial furniture, signage systems, or lightweight frames, we ensure your material arrives ready to perform.

Comparing the Two Aluminium 7075 vs 6061: Which Alloy is Right for You?

The decision between aluminium 7075 and 6061 comes down to your specific application and performance expectations. If ultimate strength and resistance to fatigue are essential, 7075 is the alloy to consider. It’s more rigid, more durable under load, and more suited to high-performance requirements.

If, on the other hand, your project requires a balance of strength, corrosion resistance, and ease of fabrication, 6061 provides tremendous value. It allows for simpler welding and finishing processes and is generally more budget-friendly. For most structural applications where maximum tensile strength isn’t critical, 6061 does the job exceptionally well.

At PT Alexindo, we take pride in helping clients navigate these decisions. We don’t just deliver material—we deliver insight. Our specialists are always ready to offer technical support, suggest alternatives, and even help with alloy comparison testing when needed. With us, you’re not just choosing a material; you’re choosing a partner committed to your project’s success.

Applications That Define Each Alloy

When it comes to real-world usage, the distinctions between 7075 and 6061 become even more apparent. Aluminium 7075 finds its home in the most demanding fields—military-grade equipment, aerospace structural components, precision firearms, and racing vehicles. In these scenarios, the slight weight advantage paired with superior strength is worth the added cost and fabrication complexity.

Meanwhile, 6061 remains the backbone of many industries. Construction, transportation, consumer electronics, and even home décor industries rely heavily on this alloy. It’s easier to anodize, polish, and weld, which makes it ideal for customisation and aesthetic purposes, alongside structural dependability.

At PT Alexindo, we have worked with both materials for decades. We’ve seen firsthand how each performs in the field, and our team is always ready to recommend the right alloy based on intended use, budget, and performance criteria.

Why PT Alexindo Is the Aluminium Partner You Can Trust

For more than 40 years, PT Alexindo has stood at the forefront of aluminium extrusion and innovation in Indonesia. We are more than a manufacturer—we are an engineering solutions provider. With modern facilities and a customer-first philosophy, we have earned the trust of clients across the construction, automotive, marine, electrical, and energy industries.

We produce and supply aluminium extrusions from start to finish with the highest standards of quality. Our capabilities include custom extrusions for 7075 and 6061, precision cutting, surface treatments, and extensive inventory management. We make sure our aluminium solutions fit seamlessly into your workflow.

Clients come to us not only for material but for assurance—knowing their supplier understands performance standards, industry trends, and the ever-growing demand for quality and innovation. And when it comes to choosing between 7075 and 6061, no one is better equipped to help than the team at PT Alexindo.

Order Your Aluminium 7075 or 6061 with Confidence

When you’re ready to move forward with your aluminium requirements, whether 7075, 6061, or a completely customized profile, our team at PT Alexindo is here to support you at every step. You can reach our main office at:

PT. ALEXINDO (Aluminium Extrusion Indonesia)

Jl. Raya Bekasi Km. 28.7, Jawa Barat 17124, Indonesia

Phone: +62 21 884 3460

Fax: +62 21 884 2301 / +62 21 884 2356

Email (Local): info@alexindo.com

Email (Export): alexindo-sales@cbn.net.id

Email (Finished Goods): infofg@alexindo.com

For plant-specific or steel division requirements, contact:

PT. ALEXINDO – Plant 2

Kawasan Industry Mandala Pratama Permai, Dawuan, Cikampek, Jawa Barat 41373, Indonesia

Phone: +62 264 8330 377 / 088 / 192

Fax: +62 264 8330 377

Email: marketing.steel@alexindo.com

Choose PT Alexindo, and let’s shape your vision in aluminium—stronger, smarter, and tailored to perform.